The main difference between hot rolled and cold rolled stainless steel is a process. Hot rolling refers to processing performed with heat, and cold rolling refers to processes performed at or near room temperature. While these processes affect overall properties and application, they should not be confused with the formal specifications and grades of steel, metallurgical composition and Property Grades Steels of different grades and specifications can be hot-rolled or cold-rolled, including basic carbon steels and other alloy steels.

This may seem obvious, but certain types of steel are better for certain applications. Knowing which material to use can avoid raw material waste. It also saves extra processing time and money. Knowing the difference between hot and cold steel is integral to the selection of hot and cold steel.

Hot rolled stainless steel is stainless steel that is rolled at very high temperatures. Hot rolled stainless steel is steel that is rolled at extremely high temperatures in excess of 1700°F (above the recrystallization temperature of most steels). This makes the steel easier to form and results in a product that is easier to handle.

To process hot-rolled steel, manufacturers first start with a large rectangle of metal, called a billet. The billets are heated and then sent to pretreatment, where they are flattened into a large coil. From there, it is held at a high temperature and passed through a series of rollers to achieve its finished size. White-hot strands of steel are pushed through the rollers at high speed. For sheet metal, rolled steel is coiled and cooled. For other forms, such as strips or boards, the material is divided and packaged.

Steel shrinks slightly as it cools. Because hot-rolled steel is cooled after processing, there is less control over its final shape, making it less suitable for precision applications. Hot rolled steel sheets are often used in applications where small dimensions are not critical. Railroad tracks and construction projects often use hot rolled steel.

Hot rolled steel can often be identified by the following characteristics: a scaled surface, remnants of cooling from extreme temperatures; slightly rounded corners (due to shrinkage and poor precision) in bar and sheet products; slight deformation, cooling may Resulting in a slightly trapezoidal form, rather than a perfectly squared angle.

What are the benefits of hot rolled stainless steel?

Hot rolled stainless generally requires less machining than cold rolled steel, which makes it less expensive. Because hot rolled steel can be cooled at room temperature, it is basically standardized, that is, the quenching or work hardening process does not create internal stresses.

Hot rolled steel is ideal when dimensional tolerances are not as important as overall material strength and surface finish is not a critical issue. If surface finish is a concern, scaling can be removed by grinding, sandblasting, or pickling in an acid bath. Once descaled, various brush or mirror treatments can also be applied. Descaled steel also provides a better finish for painting and other surface coatings.

Cold-worked steel is generally harder and stronger than standard hot-rolled steel. Cold rolled stainless steel is essentially hot rolled stainless steel that has been further processed. Once the hot rolled steel has cooled, it is then re-rolled at room temperature for more precise dimensions and better surface quality.

Although technically cold rolling applies only to sheet material that is compressed between rolls, cold rolling stainless steel is often used to describe a range of finishing processes. Pulled rebar, such as rebar or steel pipe, is "stretched" rather than rolled. Other cold working processes include turning, grinding and polishing, each of which is used to transform existing hot-rolled materials into more refined products.

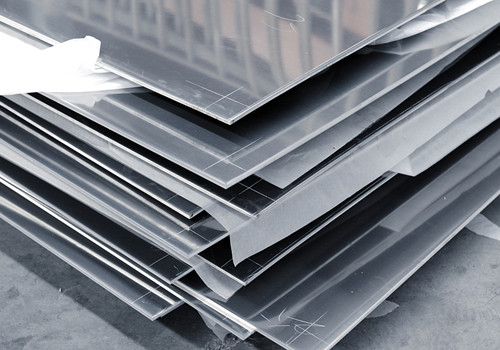

Cold rolled stainless steel can generally be identified by the following characteristics: better, more finished surface; tighter tolerances; smooth surface; cold rolled bar usually has well-defined corners; cold rolled stainless tube has better concentric uniformity and straightness.

What are the benefits of cold rolled stainless steel?

Due to its better surface properties than hot rolled stainless steel, it is not surprising that cold rolled steel is often used for more precise technical applications or important aesthetics. But the price is higher due to the additional processing of the cold finished product.

In terms of physical properties, cold rolled stainless steel is generally stronger and stronger than standard hot rolled steel. As the metal is formed at lower temperatures, the hardness, tensile fracture resistance and deformation resistance of the steel are all increased by work hardening.

However, these additional treatments also create internal stresses within the material. Unpredictable warpage can result if stainless steel is not stress relieved prior to cutting, grinding or welding.