MVC (MIXED VARIABLE CROWN) Hybrid convex roller technology is a advanced roller -shaped technology specially developed by the North Science and Technology Industrial Research on the high -second wave -shaped shape of the mid -wide wide rolling machine. The hot -rolled work roller -shaped curve makes the work roller shape have the ability to control high wave shapes.

Unlike the medium wide rolling machine, the width specifications of Delong 2680 ultra-wide rolling machine producing steel products are very large. The convex roller of HVC (High-Performance Variable Crown) requires HVC (High-Performance Variable Crown). The convex control requirements of steel width. Because the secondary curve component of the MVC roller is lacking in the face control of different width band steel, it has to be used to make up for the shortcomings through grinding multiple rollers. A occasion. In view of this, the high -level compensation ideas that follow the MVC roller shape, and supplement the advantages of the shape of the convexity roller. After theoretical derivation and simulation calculation, the new MVCPLUS work roller shape is finally designed.

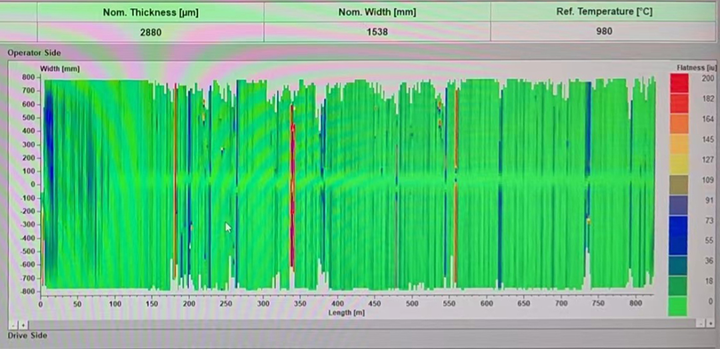

The MVCPLUS working roller shape is a working roller shape that takes into account the convexity and high -dimensional wave -shaped control. It specifically refers to the design of the rolling machine using the roll axis, and the design of the whole rack work roller curve and the upstream and downstream of the upstream and downstream The reasonable configuration of the roller shape of the rack can achieve the purpose of improving steel convexity and high wave shapes at the same time. This roller adopts the method of HVC high -efficiency convex curve and high -dimensional curve superposition, so that the working roller shape has the ability to control low -dimensional features such as convexity, middle waves and bilateral waves, and control The ability of high waves.

At present, all fine -rolled racks use MVCPLUS working rollers to effectively eliminate a quarter of wave defects. The technical advantage of this roller is that it can not only meet the control of convexity, medium waves, bilateral waves, and high wave shapes of ultra -wide stainless steel production lines. Multi -specifications of plate -shaped control, the general roller configuration has greatly shortened the preparing roller cycle of the working roller, which reduces the pressure of the roller between the grinding roller.

In addition, around the MVCPLUS roller shape, it is optimized and upgraded in the aspect of the plate -shaped setting calculation model, the intelligent channeling roller strategy, and the optimization of the plate process parameters, which improves the rolling efficiency and plate quality. Quality and efficiency.

The successful practice of the hottest stainless steel hot rolling line in the world has fully proved the advanced nature of the MVCPLUS roller. The roller has been promoted and applied in many domestic hot -rolled production lines such as Baosteel 2250, which has enhanced the ability to control the high -end complex plate defects of high -end complicated board, and solves the common problems of the industry.