430 stainless steel is a general steel type with good corrosion resistance. Its thermal conductivity is better than the austenite stainless steel, the thermal expansion coefficient is lower than the Austernous stainless steel, and it has enough heat and fatigue. Element titanium, welded seams have good mechanical properties.

430 stainless steel is often used in the manufacture of building decoration, fuel -burning parts, home appliances, and home appliances. 430F Stainless Steel is a type of steel species that adds easy cutting performance on the basis of 430 stainless steel. It can be used for automatic lathe, bolts and nuts. 430LX is added to 430 stainless steel to add titanium or pyrine or reduce carbon content, improve the processing performance and welding performance of the material. , Family durable appliances, bicycle flywheels, etc.

The corrosion resistance of 430 stainless steel in the oxidation environment is strong, but the corrosion resistance in non -oxide and activated solutions can only be used as a corrosion material for making acetic acid equipment.

430 stainless steel can resist crystal corrosion. The solubility of carbon species and nitrogen of iron body steel and nitrogen is less than the austenitic stainless steel. Because chromium and carbon spread quickly in the iron body, it is easy to form carbides. The corrosion characteristics are different from the austenitic stainless steel.

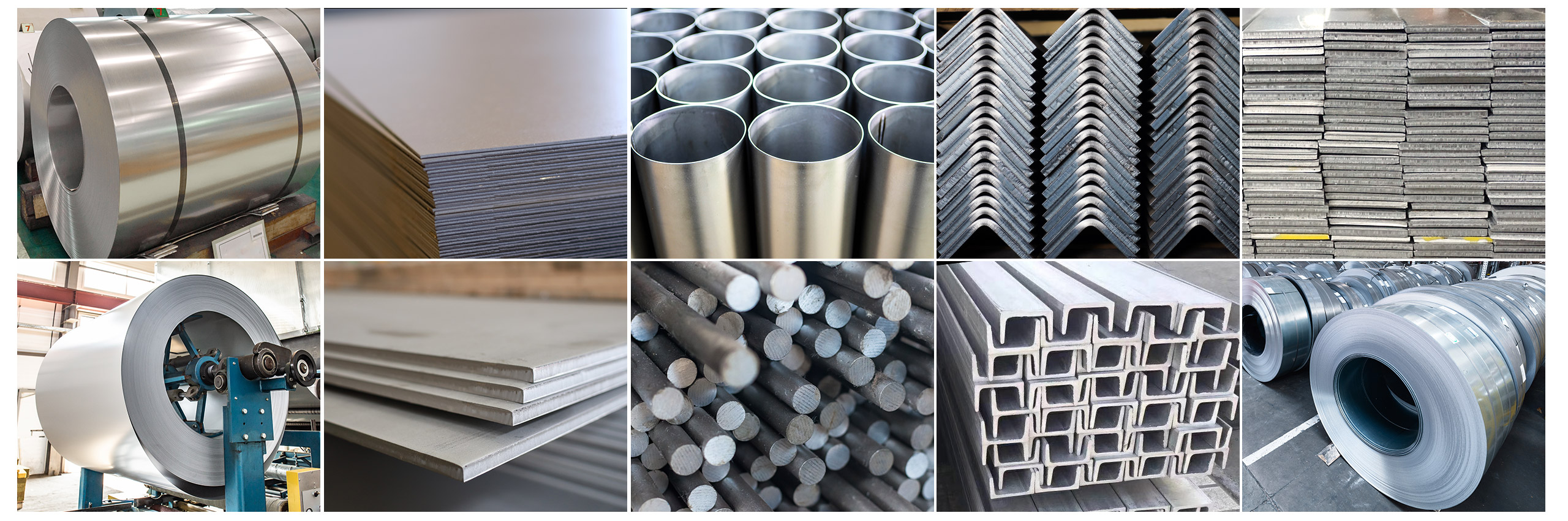

430 stainless steel has the following states, and the state is different. There are also differences in the resistance and corrosion resistance of materials, which are 2D, 2B, N0.4, HL, BA, and various other surface treatment states.

Among them, the 2D surface is slightly shiny silver white, and is washed, cold -rolled, and annealing pickles through hot rolling, annealing injection spray acid; 2B surface is silver -white and more luster than 2D surface. Spray ball acid washing, cold rolling, annealing pickling and quality rolling; good gloss and coarse patterns are polished and rolled with 100-120 grinding materials for 2D or 2B surfaces. Fine lines are polished and rolled with 2D or 2B with 150-180 grinding materials; the HL surface is silver-gray and has a silk stripe. Polish the grinding material with appropriate granularity on the 2D or 2B surface to make the surface present to the surface so that the surface is presented to make the surface presented to present the surface. Continuous grinding.