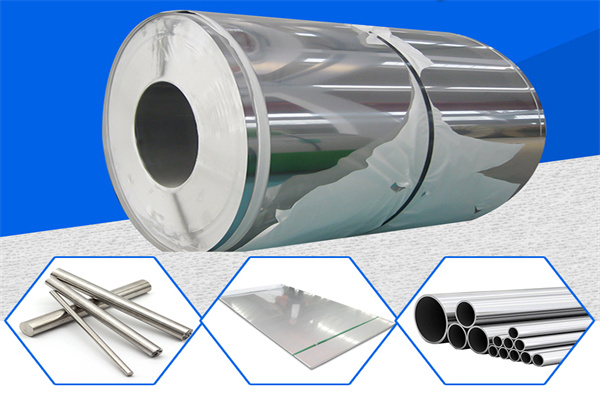

202 Stainless Steel Coil

--AISI 202

--UNS S20200

--EN 1.4373

Product Description

202 stainless steel is a type of Cr-Ni-Mn stainless with similar properties to A240/SUS 302 stainless steel. 202 stainless steel’s toughness at low temperatures is excellent.It widely used precipitation hardening grades, and possesses good corrosion resistance, toughness, high harness, and strength.

Quick Detail

| Grade | 202 stainless steel coil |

Thinckness | 0.3-6mm |

Widthness | 1000mm, 1219mm, 1524mm or as customized |

Length | as customized |

Brand name | LISCO |

Standard | JIS, AISI, ASTM, GB, DIN, EN ,etc. |

Finish | 2B, Hairline, No.4, BA, 8K mirror, Etching,etc. |

Certification | SGS |

Packaging | Standard exporting packing; seaworthy package. |

MOQ | 2 Tons |

Applications

202 stainless steel can be made into plates, sheets, and coils to be used in the following:

Restaurant equipment

Cooking utensils

Sinks

Automotive trim

Architectural applications such as windows and doors

Railway cars

Trailers

Hose clamps.

Corrosion Resistance

202 stainless steel’s Corrosion resistance is the same as 304, section 202 is stainless steel, nickel can replace 304.

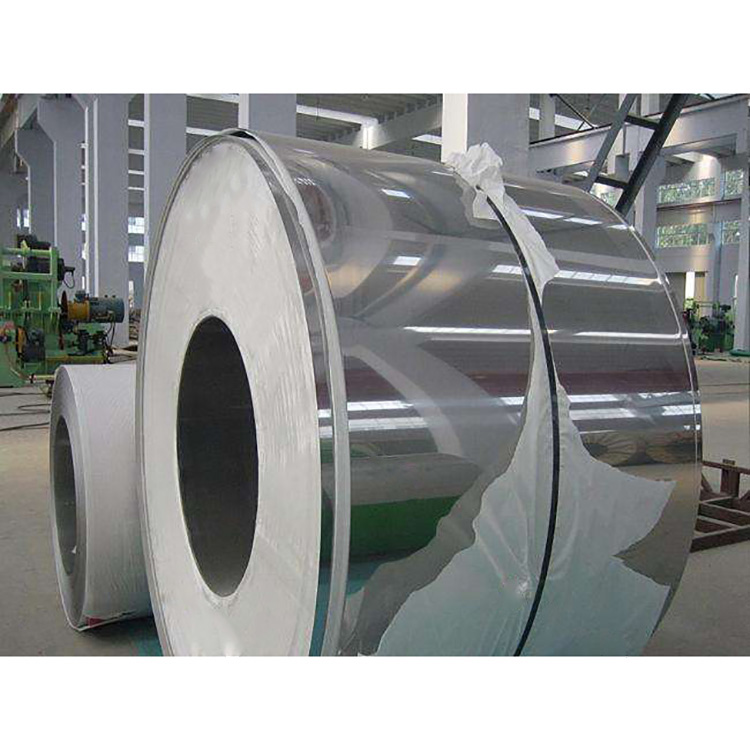

Product Show