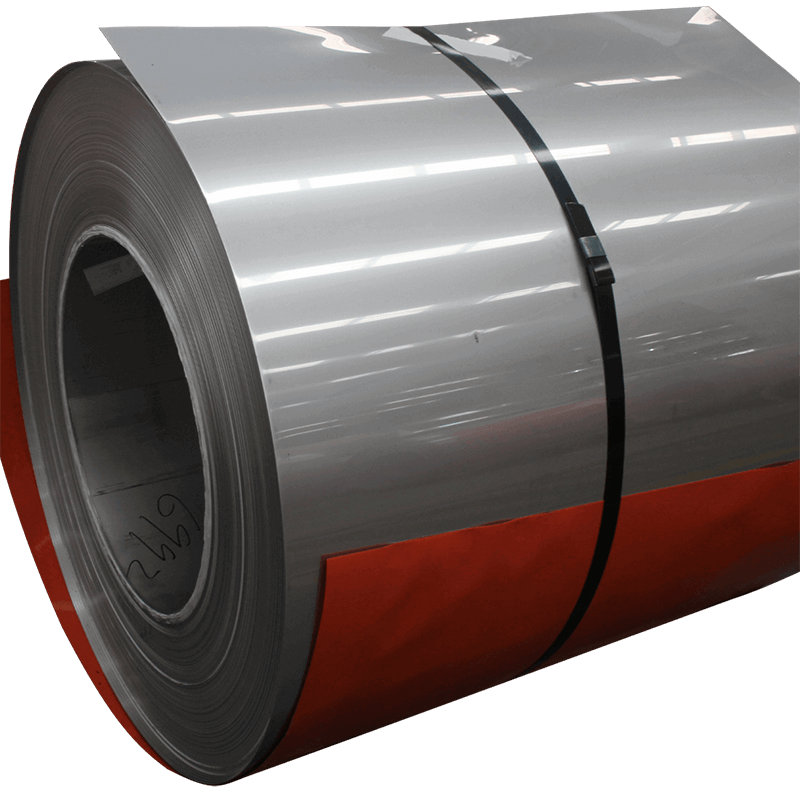

304 Stainless Steel Coil

--AISI 304

--UNS S30400

--EN 1.4301

Product Description

304 is the most versatile and widly used of all the stanless steels.Their chemical composition,mechanical properties,weldability and corrosion/oxidation resistance provides the best all-round performance at relatively lower cost.

304 stainless steels have excellent low-temperature properties and do well to hardening by cold working.They can carefully controlled chemical compositions of various sub-grades provide a largr-scale of cold work hardenability,enabling them to suit for various applications by direct drawing without intermediate annealing.

Product Show

Packing Show

Chemical Composition and mechanical properties

304 | C | Mn | P | S | Ni | Cr |

≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~10.50 | 17.00~19.00 |

tensile strength σb(MPa) | yield strength σ0.2(MPa) | elongation δ5(%) | Hardness HB |

≥520 | ≥205 | ≥40 | ≤200 |

Corrosion Resistance

304/304L stainless steels exhibit excellent resistance to a wide range of atmospheric,chemical,textile,petroleum and food industry exposures.

Oxidation Resistance

The maximum temperature to 304/304L stainless steels can be exposed continuously without apperciable scaling is about 899℃.For intermittent exposure,the maximum exposure temperature is about 816℃.

Formabilty

304/304L stainless steels have very good drawability.Their combination of low yield strength and high elongation permits successful forming of complex shapes.However,these grades work harden rapidly.To relieve stresses produced in severe forming or spinning,parts should be full annealed or stressrelief annealed as soon as possible after forming.

Wachinability

Like most other austenitic steels,these grades machine with roung and stringy chips;theredore,chip curlers can be beneficial.