316L welded Stainless Steel pipe/tube

316L welded Stainless Steel pipe/tube

Type 316L stainless steel in a molybdenum bearing austenitic. It is more resistant to general corrosion and pitting than conventional nickel chromium stainless steels such as 302-304.

MOQ:20 Tons

316L welded Stainless Steel pipe/tube

--AISI 316L

--UNS S31603

--EN 1.4404

Product Description

Type | 316L welded stainless steel pipe/tube |

Thinckness | 0.5-70mm |

Outer diameter | 6-762mm |

Length | 6m or as customer's requirement |

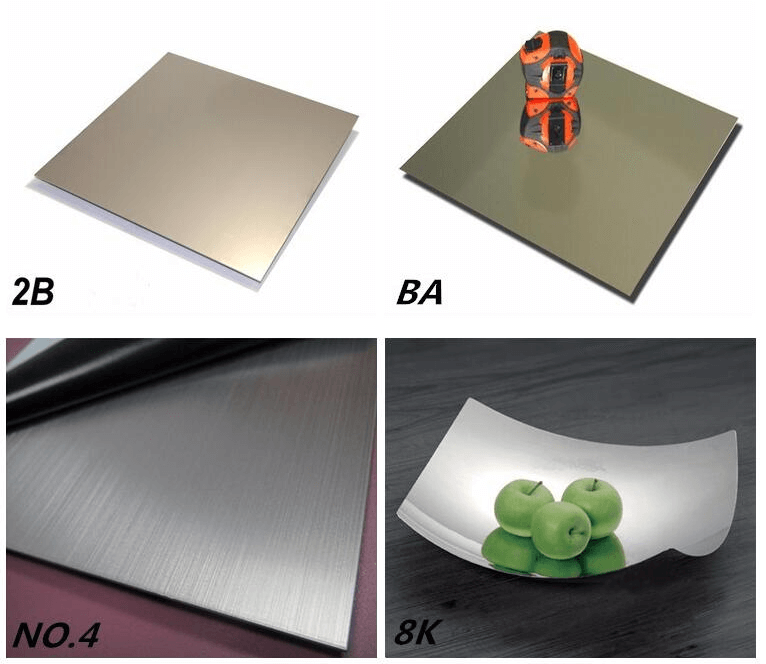

Finish | Polished, Pickled,hairline,mirror |

Shape | Round,square, rectangular,oval |

Technology | Seamless,weld |

Standard | JIS, AISI, ASTM, GB, DIN, EN ,etc. |

MOQ | 2 Ton |

Application | decoration, industry, etc. |

Certificate | SGS |

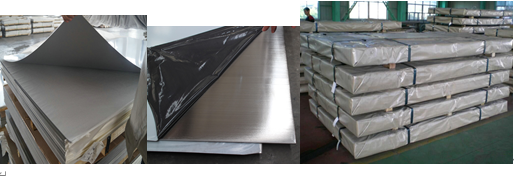

Packaging | Standard exporting packing |

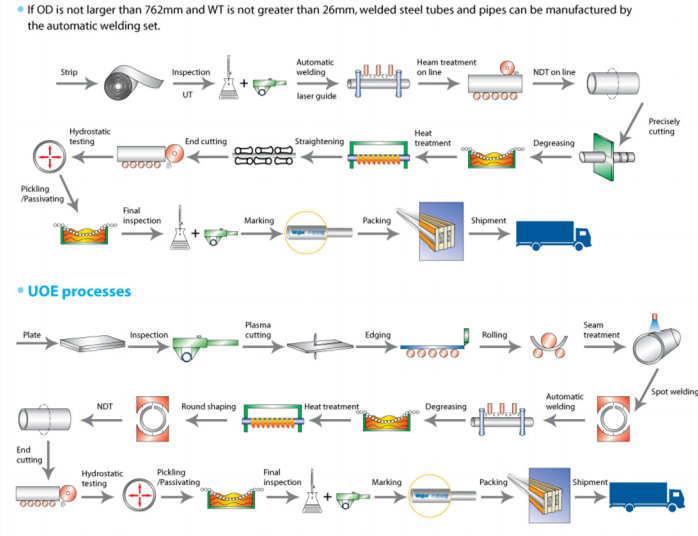

Production Processes

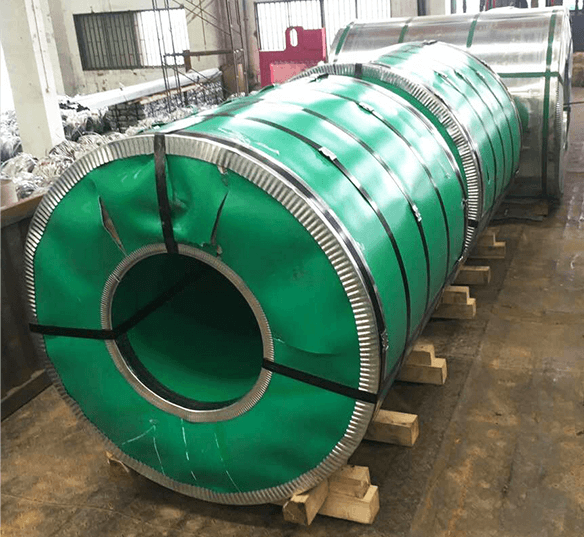

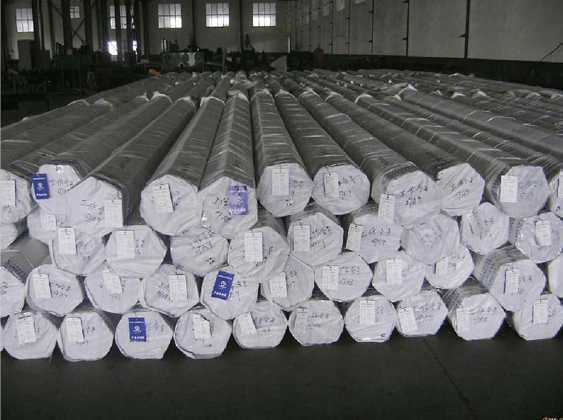

Factory Show

Feedback from contact with us

Contact us

Related Products

316/316L Stainless Steel Sheet

Both 316 and 316L stainless steel provide an extra level of resistance to atmospheric corrosion, to many organic and inorganic chemicals and to food and beverages.

Read more >

310S Stainless Steel Sheet/Plate

Stainless steel 310/310S is an austenitic heat resistant alloy with excellent resistance to oxidation under mildly cyclic conditions through 2000°F.

Read more >

430 Stainless Steel Coil

SS430 is a low-carbon plain chromium,ferritic stainless steel without any stabilization of carbon and nitrogen with titanium or niobium.

Read more >