410 Stainless Steel Sheet/Plate

--AISI 410

--UNS S41000

--EN 1.4006

Product Description

As a martensitic stainless steel, low carbon steel, when tempered 410 has good hardness and high toughness. In order to be technically classified a 410 stainless steel it needs to contain a minimum of 11.5 percent chromium. This property, as well as because of its strength and durability, makes 410 stainless have an overall good corrosion resistance.

Product Detail

| Grade | 410 stainless steel sheet |

Thinckness | 0.3-6mm |

Widthness | 1000mm, 1219mm, 1524mm or as customized |

Length | 2438mm, 3048mm, 6096mm or as customized |

Brand name | TISCO,BAO Steel,ZPSS,BAO XIN,LISCO.. |

Standard | JIS, AISI, ASTM, GB, DIN, EN ,Etching, etc. |

Finish | 2B, Hairline, No.4, BA, 8K mirror, etc. |

Certification | SGS |

Packaging | Standard exporting packing; seaworthy package. |

MOQ | 2 Tons |

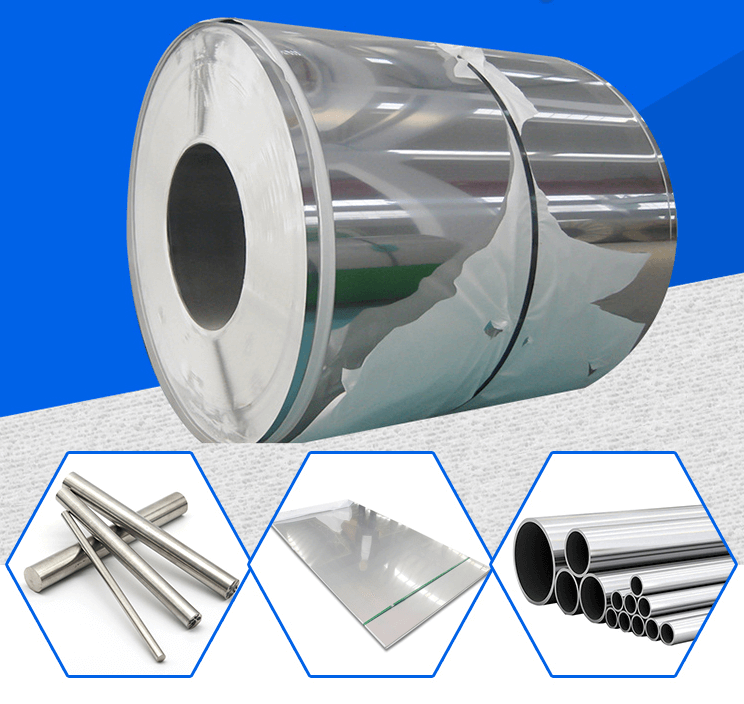

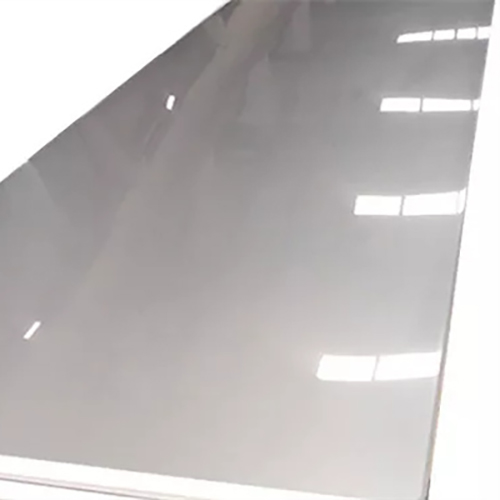

Product Show

Chemical Composition and mechanical properties

| 410 | C | Si | Mn | P | S | Cr |

≤0.15 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 11.50~13.50 |

tensile strength σb (MPa) | yield strength σ0.2(MPa) | elongation δ5(%) | Hardness HB |

≥440 | ≥205 | ≥20 | ≤210 |

Corrosion Resistance

SS410 provides good corrosion resistance to air,water and some chemicals.It shows satisfactory resistance to nitric acid,concentrated sulfuric acid,concentrated sulfuric acid,dilute acetic acid and naptha.Resistance to food acids is good.

Annealing

Annealing is achieved by heating to above 816℃ and 899℃for 90 minutes per 25mm thickness followed by air quenching.Controlled atmospheres are recommended in order to avoid excessive oxidation of the surface.

Welding

The martensitic class of stainless steeks has limited weldability due to its hardnability.Special consideration is required to avoid cold cracking by preheating to 260℃.Post-weld heat treatment should be considered to achieve required properties.This particular alloy is generally considered to have the best weldability of this stainless class.