430 Stainless Steel Sheet/Plate

430 Stainless Steel Sheet/Plate

Stainless steel grade 430 is a non-hardenable steel containing straight chromium, and belongs to the ferritic group of steels. This steel is known for its good corrosion resistance and formability, coupled with practical mechanical properties.

MOQ:10 Tons

430 Stainless Steel Sheet/Plate

--AISI 430

--UNS S43000

--EN 1.016

Product Detail

| Grade | 430 stainless steel sheet |

Thinckness | 0.3-6mm |

Widthness | 1000mm, 1219mm, 1524mm or as customized |

Length | 2438mm, 3048mm, 6096mm or as customized |

Brand name | TISCO,BAO Steel,ZPSS,BAO XIN,LISCO.. |

Standard | JIS, AISI, ASTM, GB, DIN, EN ,etc. |

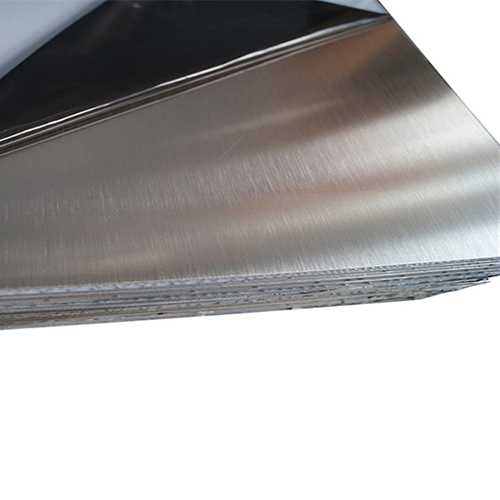

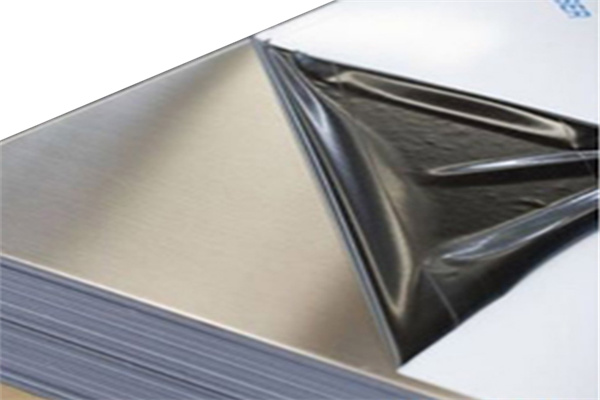

Finish | 2B, Hairline, No.4, BA, 8K mirror, etc. |

Certification | SGS |

Packaging | Standard exporting packing;seaworthy package. |

MOQ | 2 Tons |

Product Show

Feedback from contact with us

Contact us

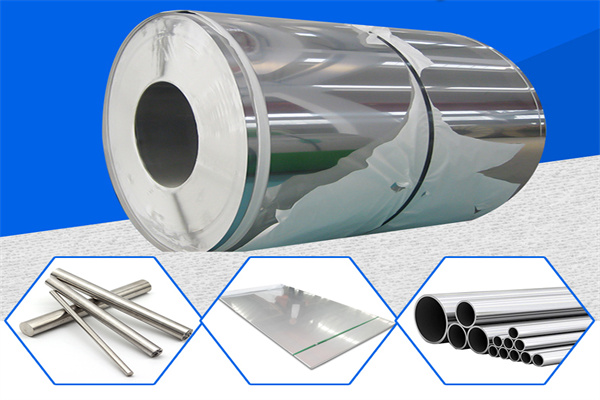

Related Products

316/316L Stainless Steel Sheet

Both 316 and 316L stainless steel provide an extra level of resistance to atmospheric corrosion, to many organic and inorganic chemicals and to food and beverages.

Read more >

310S Stainless Steel Sheet/Plate

Stainless steel 310/310S is an austenitic heat resistant alloy with excellent resistance to oxidation under mildly cyclic conditions through 2000°F.

Read more >

430 Stainless Steel Coil

SS430 is a low-carbon plain chromium,ferritic stainless steel without any stabilization of carbon and nitrogen with titanium or niobium.

Read more >