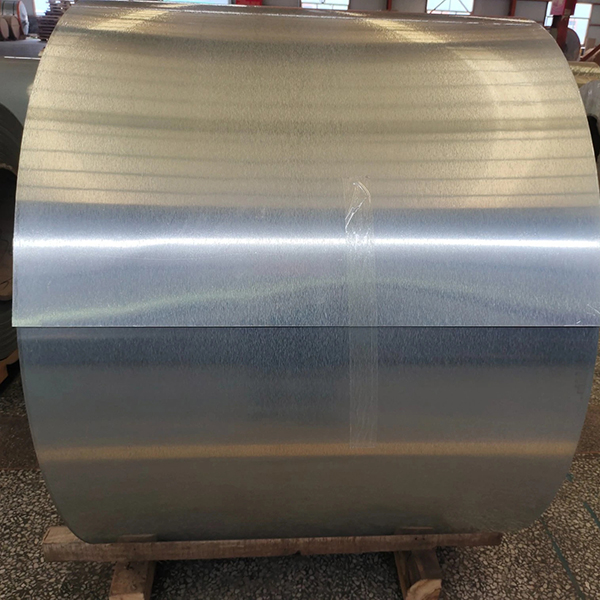

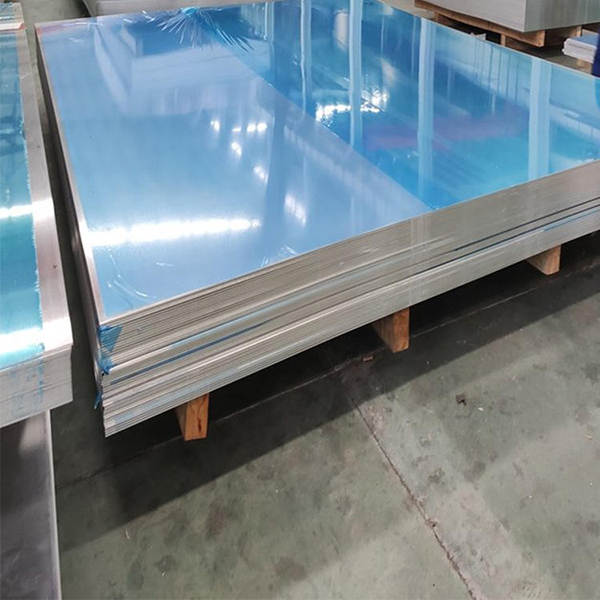

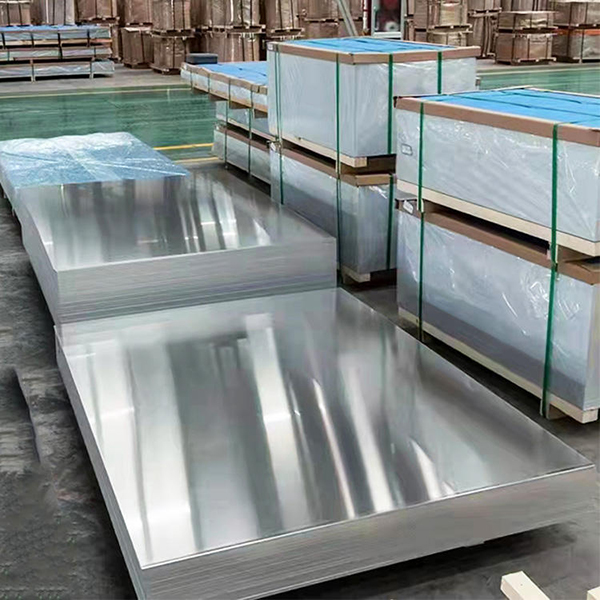

Introduction of aluminum plate

| Product | 5A03/5A06/5A05/5A02/5052/5083/5754/5182 Aluminum plate |

| Temper | O/H12/H14/H16/H22/H24/H112/H116/H321 |

| Grade | 1000series:1050/1060/1070/1080/1100/1350 |

| 2000series:2011/2014/2017/2024 | |

| 3000series:3002/3003/3104/3204/3030 | |

| 5000series:5005/5025/5052/5040/5054/5056/5083/5152 | |

| 6000series:6101/6003/6061/6063/6020/6201/6262/6082 | |

| 7000series:7003/7005/7050/7075 | |

| 8000series:8011 | |

| Thickness | 1.0-150mm |

| Width | 100-2200mm |

| Length | 500-10000mm |

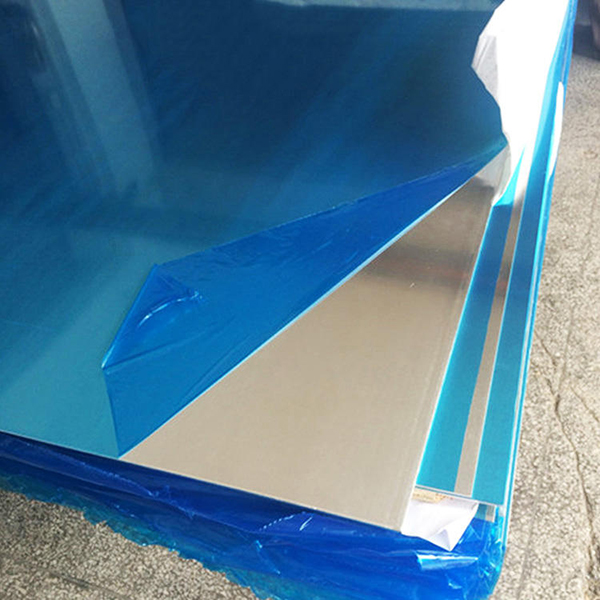

| Service | Perforated, Cutting special size, Doing flatness, Surface treatment,etc |

| Executive Standard | GB/DIN/ANSI/BS/JIS/ASTM/BS |

| Certificate | SGS/BV/MTC/IOS/CE |

| Delivery time | 7-15 days after deposit |

| Container Info | 20ft GP: L5.8m * W2.13m * H2.18m , about 27 CBM, Loading Max.26 Tons |

| 40ft GP: L11.8m * W2.13m * H2.18m, about 54 CBM, Loading Max.26 Tons | |

| 40ft HG: L11.8m * W2.13m * H2.72m, about 68 CBM, Loading Max.26 Tons |

Mechanical Properties

| Product | Tensile strength σb (MPa) | Yield strength σ0.2 (MPa) | Elongation δ5 (%) | Hardness(HB) |

| 5A03-H112 | 175 | 80 | 15 | / |

| 5A06-H112 | 305 | 145 | 12 | / |

| 5A05-H112 | 265 | 115 | 14 | / |

| 5A02-H112 | 147 | / | 14 | / |

| 5052-H32 | 210-260 | 130 | 5 | 61 |

| 5083-H112 | 275 | 125 | 10 | 75 |

| 5754-O | 190-240 | 80 | 12 | 38 |

| 5182-O | 175 | 80 | 15 | 70 |

Chemical Composition

| Product | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Others | |

| 5A03 | 0.5-0.8 | 0.5 | 0.1 | 0.3-0.6 | 3.2-3.8 | / | 0.2 | 0.15 | / | Single | Total |

| 0.05 | 0.15 | ||||||||||

| 5A06 | 0.5 | 0.4 | 0.1 | 0.5-0.8 | 5.8-6.8 | / | 0.2 | 0.02-0.10 | / | 0.05 | 0.15 |

| 5A05 | 0.5 | 0.5 | 0.1 | 0.3-0.6 | 4.8-5.5 | / | 0.2 | / | / | 0.05 | 0.15 |

| 5A02 | 0.4 | 0.4 | 0.1 | 0.15-0.40 | 2.0-2.8 | / | / | 0.15 | / | 0.05 | 0.15 |

| 5052 | 0.2-0.8 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | / | / | 0.05 | 0.15 |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | / | 0.05 | 0.15 |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | 0.2 | 0.15 | / | 0.05 | 0.15 |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.1 | 0.25 | 0.1 | / | 0.05 | 0.15 |

The corrosion resistance and tensile strength of 5A03 are higher than 5754, and the welding performance is better than 5754. It can be used for gas welding, argon arc welding, spot welding and roll welding.

5A06 has high strength, corrosion resistance and stability. The gas tightness and weld plasticity of argon arc welding weld are qualified. The strength of the welded joint of gas welding and spot welding is 90 ~ 95% of the base strength, and the machinability is good.

5A05 has high plasticity in annealed state, good corrosion resistance and acceptable weldability. Suitable for spot welding, atomic hydrogen welding, gas welding and argon arc welding.

5A02 has high plasticity, good formability and weldability. Cold deformation can improve its strength, has good corrosion resistance, and is suitable for use in marine environment.

5052 has good molding performance and corrosion resistance. It is the most widely used antirust aluminum.

5754 aluminum plate products have excellent corrosion resistance, excellent processing performance, weldability and easy processing formability.

5182 has good corrosion resistance, good weldability, good cold workability and medium strength. It is widely used in automotive lightweight aluminum.