Galvanized Steel Plate

The advantage properties of Electro Galvanized Steel (EGI) are tough coating, completed protection, low maintenance and long life.Electro Galvanized Steel (EGI) combines utility with beauty. The composition of hot dip galvanized steel consists of tin, chrome, zinc, paint or plastic that has an extra finish applied to the natural steel surface. The application of the coating is done in order to protect the surface of the steel from oxidation and it is also used to enhance requirements for visual appearance.

Product Specification and Steel Grade (For Reference)

Specifications | JIS G3313 SECC | JIS G3313 SECD | JIS G3313 SECE |

Application | Commercial Quality | Drawing Quality | Deep Drawing Quality |

Usage | Furniture, Computer Case, Electronic Parts, Electrical Equipment | Automobile | Automobile |

Type of Surface Treatment | Chromate Treatment, Phosphate Treatment, Oiling | ||

Available Size | Thickness: 0.3~1.6mm | ||

Width: 850~1580mm | |||

Coating Weight: 10-30g/m (single side) | |||

Max. Coil Weight: ≦ 20 MT | |||

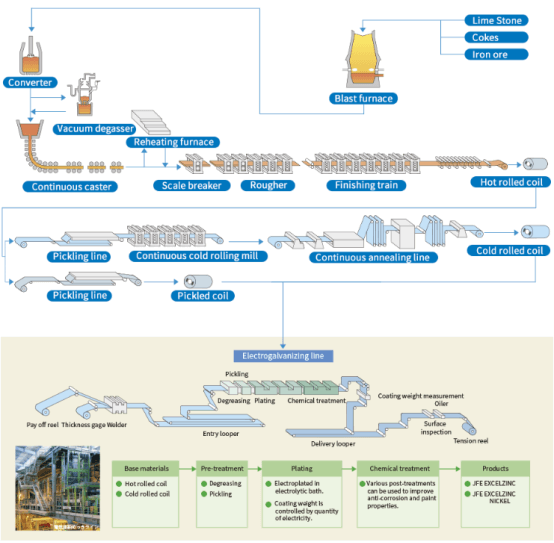

Manufacturing process

Application

Electro-galvanized steel has a good appearance and is widely used indoors.Electro-galvanized steel is an ideal material for manufacturing applications and shows excellent formability.Typical applications of electrically galvanized steel include door frames, sound-proof ceiling tiles, automobile panels, and switchboards.